Blog Blog

What Does a Field Heat-Treating Company Do?

September 28, 2023

What Does a Field Heat-Treating Company Do?

September 28, 2023Title: What Does a Field Heat-Treating Company Do?

Introduction

In the world of heavy industry, where metals are molded, forged, and shaped into essential components for various applications, the role of heat treatment cannot be overstated. Heat treatment is a critical process that enhances the mechanical properties of metals, making them stronger, more durable, and better suited for their intended purposes. Field heat-treating companies play a pivotal role in ensuring that this vital process is carried out efficiently and effectively, often on-site at industrial facilities. In this comprehensive blog post, we will delve into what a field heat-treating company does, its significance in the industry, and the various services it offers.

Understanding Heat Treatment

Before we explore the functions of a field heat-treating company, it’s crucial to understand the basics of heat treatment. Heat treatment is a controlled process of heating and cooling metals to alter their physical and mechanical properties without changing their shape. This process typically involves the following stages:

- Heating: The metal is heated to a specific temperature using various methods, including induction heating, gas heating, or electric heating.

- Soaking: Once the desired temperature is reached, the metal is held at that temperature for a predetermined period, allowing for uniform heat distribution.

- Quenching: The metal is rapidly cooled by immersing it in a quenching medium (usually oil, water, or air) to achieve the desired hardness and structure.

- Tempering: To relieve internal stresses and achieve the desired balance between hardness and toughness, the metal is reheated to a lower temperature.

- Inspection and Testing: After heat treatment, the metal undergoes inspection and testing to ensure it meets the specified quality and performance standards.

Now, let’s explore the roles and responsibilities of a field heat-treating company in this intricate process.

The Core Functions of a Field Heat-Treating Company

- On-Site Heat Treatment

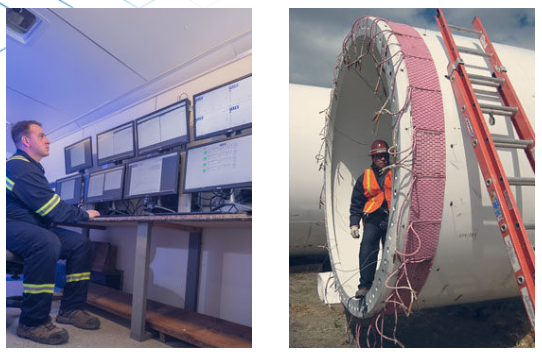

Field heat-treating companies specialize in providing on-site heat treatment services to industries such as oil and gas, power generation, petrochemical, aerospace, automotive, and more. One of their primary functions is to bring their expertise and equipment directly to industrial facilities, ensuring minimal disruption to the production process.

On-site heat treatment is particularly essential for large and heavy components that cannot be transported easily to a centralized heat-treating facility. This includes items like pressure vessels, pipelines, turbine blades, and various industrial machinery parts.

- Preheat and Post-Weld Heat Treatment

Field heat-treating companies play a crucial role in preheat and post-weld heat treatment, which are essential for welding processes. Preheat treatment involves heating the base metal before welding to reduce the risk of cracking and improve weld quality. Post-weld heat treatment is performed after welding to relieve residual stresses and enhance the weld’s mechanical properties. Field heat-treating experts are responsible for ensuring that these processes are executed precisely, in accordance with industry codes and standards.

- Stress Relieving

Stress relieving is a heat treatment process that helps reduce internal stresses in metal components, making them more stable and less susceptible to deformation or cracking during service. Field heat-treating companies perform stress relieving on various industrial components, including castings, forgings, and welded assemblies. This process is critical for maintaining the structural integrity of these components.

- Annealing

Annealing is a heat treatment process that involves heating metal to a specific temperature and then gradually cooling it to make it softer and more ductile. Field heat-treating companies perform annealing services on materials such as steel, copper, and aluminum to improve their machinability, formability, and overall mechanical properties.

- Hardening and Tempering

In addition to making metals softer, field heat-treating companies also specialize in hardening and tempering processes. These treatments involve heating the metal to high temperatures, followed by rapid cooling and subsequent tempering to achieve the desired hardness and toughness. Hardening and tempering are commonly used for tools, gears, and various machine components.

- Non-Destructive Testing (NDT)

Field heat-treating companies are often equipped to perform non-destructive testing (NDT) services to assess the quality and integrity of heat-treated components. NDT techniques, such as ultrasonic testing, magnetic particle testing, and radiographic testing, help detect defects and ensure that the heat treatment process has been executed correctly.

- Quality Assurance and Compliance

Ensuring quality and compliance with industry standards and regulations is a fundamental responsibility of field heat-treating companies. They must adhere to strict quality control measures, documentation, and reporting to certify that all heat-treated components meet the required specifications and safety standards.

Conclusion

Field heat-treating companies are the unsung heroes of the heavy industry, playing a vital role in ensuring the structural integrity, performance, and safety of critical metal components. Through on-site heat treatment, preheat and post-weld treatments, stress relieving, annealing, hardening and tempering, non-destructive testing, and stringent quality assurance, these companies help industrial sectors function smoothly and safely.

In the ever-evolving landscape of manufacturing and construction, field heat-treating companies remain at the forefront of technological advancements, providing innovative solutions to meet the industry’s evolving needs. Their contributions extend far beyond the realm of metallurgy, shaping the backbone of modern infrastructure and technology. As we continue to rely on durable and high-performance metal components, the significance of field heat-treating companies in ensuring the integrity of these components cannot be overstated.